LK 2-80MT-B Duo-Press Automatic Foil stamping & Die Cutting Machine is the new generation of LK series. It is developed on the basis of Guangya’s years of experience of manufacturing of Automatic Foil Stamping and Die Cutting Machines, and of analysis of similar products by the major producers in the industry from both home and abroad as well as of suggestions from our customers.

This machine is mainly used for die-cutting, indentation, foil stamping and embossing of cartons, cartons and trademarks in the packaging and decoration industry, especially for various high-end and fine printed matters, such as cigarette boxes, wine boxes, gift boxes, and small household appliance boxes, Cosmetic boxes, etc. All of them can be embossed and indented on this machine to obtain three-dimensional, exquisite and beautiful printed products.

*Flexible production of short and small batches.

*Quick-lock version frame device, shorten the debugging time by 50%.

*With center alignment function from conveying to die cutting.

*Automatic pressure adjustment system by servo motor, higher precision and more convenient.

*Automatically decrease pressure if no paper, extend mould service life.

*Non-stop sampling function, improve work efficiency.

|

Technical Data |

LK2-80MT-B |

|

|

Suitable Material |

Cardboard |

90-2000 g/㎡ |

|

Corrugated |

≤4mm |

|

|

Plastic Sheet |

Acoordingly |

|

|

Sheet Size |

Max. sheet size |

800 X 620 mm |

|

Min. sheet size |

360 X 290 mm |

|

|

Max. die cutting size |

790 X 610 mm |

|

|

Max. foil stamping size |

790 X 610 mm |

|

|

Max. embossing size |

790 X 610 mm |

|

|

Inner Chase size |

830 X 630 mm |

|

|

Capabilities |

Max. die cutting speed |

8000 s/h |

|

Max. foil stamping speed |

6500 s/h |

|

|

Max. working pressure |

200 t |

|

|

Working accuracy |

± 0.1 mm |

|

|

Foil Stamping |

Adjustable temperature |

20 - 200 °C |

|

Heatable zones |

6 each host |

|

|

Foil shafts |

1st Host 3L2T, 2nd Host 2T |

|

|

Max. foil diameter |

250 mm(纵向) |

|

|

Pile Height |

Max. feeding height |

1280 mm |

|

Max. delivery height |

1070 mm |

|

|

Power Supply |

Main motor power rate |

15 kW |

|

Heating plates power rate |

2 kW each zone |

|

|

Total power rate |

82.5 kW |

|

|

Air supply |

0.6 Mpa, 0.37 M3/min |

|

|

Machine Dimension |

Length |

7400 mm |

|

Width |

4600 mm |

|

|

Height |

2450 mm |

|

|

Weight |

26.5 t |

|

|

*Pile height is with tray. |

||

|

*L stands for longitudinal, H stands for transversal. |

||

Non-stop Feeder

• Imported Non-stop High-Speed Feeder

• Feeder anti-collision protection

• Synchronous belt drive to ensure the accuracy of paper feeding

• Left and right movement function of pile tray

• Adjustable paper feeding side blowers

• Pre-stacking paper function, non-stop paper feeding function

Feed Table

• Imported belts

• The belt is automatically tightened, no need to adjust

• Adaptive pressure wheel

• Electrical front lays

• Push-pull integrated side guides

• Imported Antistatic pattern stainless steel

• Ultrasonic double sheet detector (optional)

Host station

• Electrically pressure adjustment function

• Automatic pressure keeping and pressure reduction function

• Imported intermittent mechanism and synchronous belt drive to ensure running accuracy

• Presetting Table (optional)

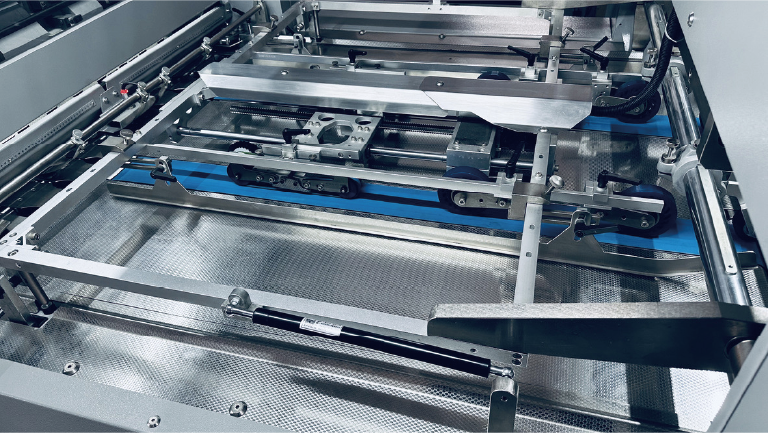

Frame and Bottom Plate

• Two-way one button locking device for chase and bottom plate

• Positioning locking function of frame and host to ensure operation accuracy

• Anti-drop protection function for chase and supporting plate

• Integrated bottom plate, change job fast

• Steel plate imported from Germany

• Quick-lock cutting board frame with center positioning

• Cutting plate fine adjustment

Host Structure

• Host with exclusive and innovative design and is made of specially treated materials

• Extremely high strength, toughness and service span

• Can withstand greater working pressure and working speed

Foil Stamping Station

• Exclusive innovative foil stamping structure

• With 3 longitudinal and 2 transverse foil shafts

• 6 independent temperature zones to avoid interstitial temperature differences

• Independent temperature control, energy efficient

• Preheating function in temperature zone, save time

• Hot stamping memory function, storing operation recipes, reduce makeready time

• Holographic foil stamping (optional)

Foil System

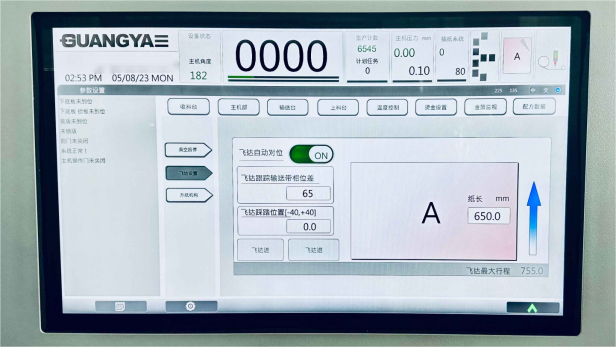

Foil Stepping Function

• Independently developed, exclusive system

• Automatic foil stepping calculation function, foil stepping optimisation function

• Up to 6 sets of irregular foil stepping with different spacing can be calculated automatically

Foil Break Detection System

• On-screen operation, easy to use

• Sensitive detection, reducing waste of aluminum foil and paper

• Independent switch

Delivery

• Non-stop sampling function

• Servo-controled braking brush with motorized adjustment function (length and angle)

• Rear jogger fine adjustment device

• Tape inseter (optional)

• Safety light curtain (optional)

• Paper delivery fan system. It can be adjusted individually; infinitely variable speed.

• Automatic intermittent lubrication system

Control System

Operating System

• 24-inch industrial control large-size true color touch capacitive screen

• Easy operation and visualized functions

• Automatic screen off function, environmental protection and energy saving

• Production operation monitoring, data statistics function.

• Imported motion control system, Ethercat real-time industrial bus structure

Electrical System

• Modular design of electrical system

• All imported electrical appliances, quality assurance

• Remote module, fast and convenient maintenance

• Air conditioner for electric cabinet (optional)

*FOR MORE DETAILS, PLEASE ASK YOUR SALES CONSULTANT